Product Feature

HVM

Sample/Test

| Product | ~ 2023 | 2024 [New Plant] |

2025 ~ |

|---|---|---|---|

| Layer Count | 2L-14L | 16L ~ | |

| Multilayer | HLC | 1+N+1 | |

| Working Panel | 622mm x 572mm 22.5" X 24.5" |

673mm x 588mm 24" X 28" |

Min Shipping Panel: 80mm / 3" Max Shipping Panel:540mm x 330mm > 596mm x 530mm 21" X 12" > 23" X 20" |

| Min 0.075mm (3mil) Max 2.0mm (80mil) |

Min 0.05mm (2mil) Max 2.0mm (80mil) |

Shipping Panel Thickness: 0.8mm ~ 2.4mm > 0.8mm ~ 4.0mm 3mil ~ 94mil > 3mil ~ 160mil Tolerance: ±10% Main Material: FR4 |

Registration Feature

HVM

Sample/Test

| Product | ~ 2023 | 2024 [New Plant] |

2025 ~ |

|---|---|---|---|

| I/L Trace Width and Space | Inner Layer: 75um / 75um 3mil / 3mil |

Inner Layer: 60um / 60um 2.4mil / 2.4mil |

Inner Layer: 50um / 50um 2mil / 2mil |

| O/L Trace Width and Space | Outer Layer: 75um / 75um 3mil / 3mil |

Outer Layer: 75um / 60um 3mil / 2.4mil |

0.5oz/18um: 60um / 60um 2.4mil / 2.4mil |

Drilling Capability

HVM

Sample/Test

| Product | ~ 2023 | 2024 [New Plant] |

2025 ~ |

|---|---|---|---|

| Press Fit Tolerance | |||

| ± 0.08um | ± 0.05mm ± 2.0mil |

|

|

| Back Drill | + 0mil - mil |

|

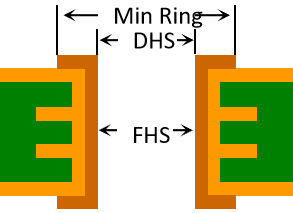

| Parameter | Specification | Remarks | |

|---|---|---|---|

| Press Fit Tolerance | |||

| Min FHS (D) | Min FHS (D) | Accuracy: ± 3mil ( CCD ) | |

| Min DHS (D)* | 8mil / 0.26mm | ||

| Min Ring (B) | d + 8mil / 0.26mm | ||

| Min AntiPad (C) | d + 18mil / 0.55mm | ||

| Back Drill | BDHS (E) | d + 6mil / 0.20mm (CCD) | |

| Stub Length (G) | 6 ± 4mil / 0.12mm | ||

| Clearance | d + 18mil / 0.55mm (CCD) ( Vacuum Plugging ) |

||

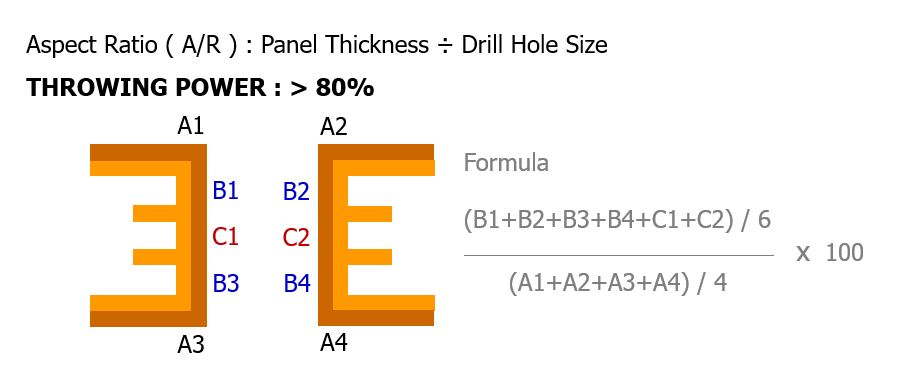

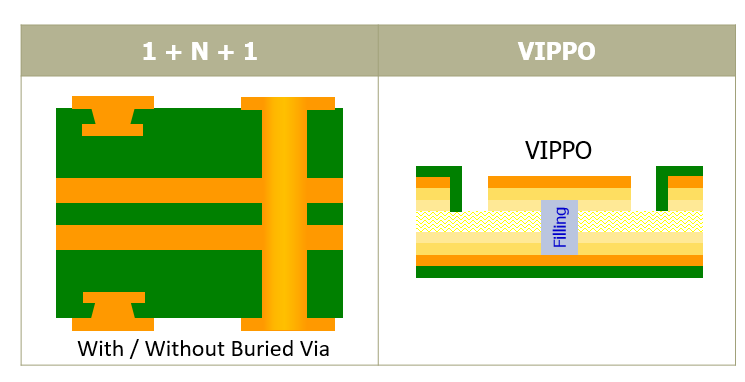

Plating Capability

HVM

Sample/Test

| Product | ~ 2023 | 2024 [New Plant] |

2025 ~ |

|---|---|---|---|

| A/R of Through Holes | A/R: 8 | A/R: 16 | |

| VIPPO (Via In Pad Plate Over) |

Solder Mask / Legend Capability

HVM

Sample/Test

| Product | ~ 2023 | 2024 | 2025 ~ [New Plant] |

|---|---|---|---|

| SM Registration | 50um / 2 mil |

|

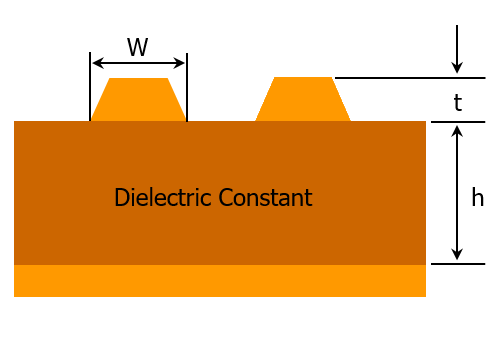

Impedance Control Capability

HVM

Sample/Test

| Product | ~ 2023 | 2024 | 2025 ~ [New Plant] |

|---|---|---|---|

| Impedance Control | Inner Layer: <10% | Inner Layer: <7% | |

| Outer Layer: <10% |

| Impedance ±10% Roadmap | Impedance ±7% Roadmap | ||

|---|---|---|---|

| Impedance Details | Control Parameters | Control Parameters | |

|

Significant Factor's 1. Dielectric Constant 2. Thickness (h) 3. Trace Width (W) 4. Trace Copper Thickness (t) |

|

|

Surface Finishing

| Product | ~ 2023 | 2024 [New Plant] |

2025 ~ | |||||

|---|---|---|---|---|---|---|---|---|

| Old / New Building | Old / New Building | Old / New Building | ||||||

| Metal Finishing | OSP | 🗸 | Old | 🗸 | New | 🗸 | New | |

| HASL | 🗸 | Old | 🗸 | 🗸 | ||||

| LF HASL | Old | 🗸 | Old | 🗸 | 🗸 | |||

| GOLD PLATING | Evaluation | Evaluation | New | 🗸 | New | |||

| GOLD PLATING | Evaluation | Evaluation | New | 🗸 | New | |||

| GOLD PLATING | Evaluation | Evaluation | 🗸 | New | ||||

| Remark | LEAD FREE HASL | |

|---|---|---|

| 🗸 | Existing |

|

| Evaluation | Initial Evaluation | |

| 🗸 | New Investment | |

Material Preference

Certified

On Progress

PSA Certified

| Material Type | Nanya | Panasonic | TUC | EMC | Kingboard | Sheng Yi | ITQ | GRACE | ||

|---|---|---|---|---|---|---|---|---|---|---|

| FR4 | Mid-Tg | Non-HF | NP-140TL FR-486 |

R-1766 | TU-662 | - | KB-6164F KB-6060F |

- | - | - |

| Mid-Tg | Non-HF (Low CTE) |

NP-155F NP-155FBH |

R-1755E R-1755M |

TU-662 | EM-825 EM-825(I) |

KB-6165F | S-1000 | IT-158TC | GA-150LL | |

| Mid-Tg | HF | NPG-151 | R-1566 | TU-747HF | EM-285 EM-370(5) |

- | S-1150G | IT-150GTC | GA-HF-15 | |

| High-Tg | Non-HF | NP-175FTL NP-175FBH |

- | - | EM-827(I) | - | - | IT-180T | GA-170LL | |

| High-Tg Mid Loss | HF 0.01-0.012 |

NPG-171 | - | TU-862HF | EM-370(D) | - | - | - | GA-LD-HF | |

| Low Loss | - | NPG-170D | - | TU-872LK | EM-888 | - | - | IT-150DA | - | |